Necessary Tips for Buying OEM Construction Parts

Necessary Tips for Buying OEM Construction Parts

Blog Article

Checking Out the Advantages of OEM Construction Components in Ensuring Seamless Operations at work Site

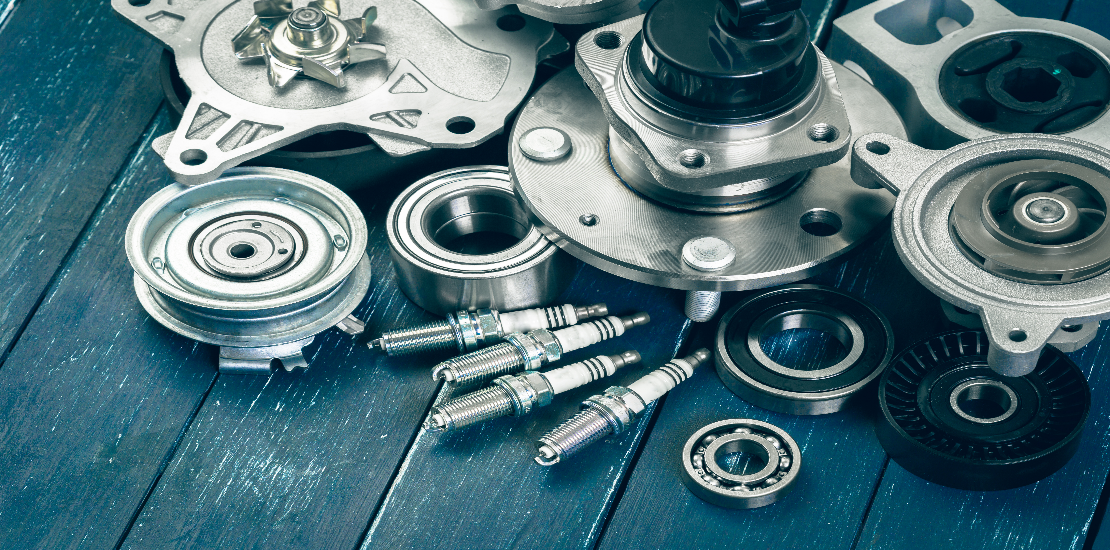

In the world of building procedures, the reliance on Original Equipment Manufacturer (OEM) building components plays a crucial duty in maintaining the performance and performance of hefty equipment and tools on work sites. These parts are developed to fulfill the specific specs and standards established by the tools producers, ensuring ideal efficiency and compatibility. As the backbone of smooth operations, the utilization of OEM construction parts uses a variety of advantages that surpass plain functionality. From bolstering devices performance to boosting safety measures and extending the life expectancy of equipment, the advantages are manifold. It is essential to discover in depth just how these OEM parts add to seamless procedures and why they remain a keystone of success in the building industry.

Boosted Devices Efficiency

Improved tools performance is a crucial aspect that underscores the significance of utilizing OEM building and construction parts. Initial Equipment Manufacturer (OEM) components are particularly made to fulfill the exact specs of the tools, making certain optimal efficiency and longevity. When building and construction firms utilize OEM parts in their machinery, they can dramatically improve the effectiveness and efficiency of their equipment on the job site.

One trick advantage of OEM building components is their compatibility with the tools they are intended for. OEM components are engineered to seamlessly incorporate with the machinery, decreasing the danger of breakdowns or breakdowns that can happen with aftermarket or generic parts (Oem Construction Parts). This compatibility translates into improved tools performance, as OEM parts preserve the designated capability and top quality of the equipment

In addition, OEM building parts go through extensive testing and quality assurance steps to meet industry requirements. This interest to detail ensures that the parts are resilient, reliable, and with the ability of standing up to the requiring problems of construction work. By making use of OEM building parts, companies can maximize the efficiency of their tools, causing increased productivity and price financial savings over time.

Reduced Downtime

By making use of OEM building and construction parts, construction companies can considerably lower downtime, consequently boosting total operational performance. Downtime on a building and construction website can be expensive, creating hold-ups in project timelines and enhancing labor costs. OEM construction components are made to fit flawlessly with the initial devices, making certain ideal performance and reducing the threat of failures.

When using OEM components, construction companies can reduce the moment needed for upkeep and repairs. OEM components are constructed to precise requirements, ensuring an ideal fit and trustworthy performance. This minimizes the opportunities of unanticipated equipment failures that can cause unexpected downtime.

Additionally, OEM components are recognized for their quality and durability, supplying longer-lasting options contrasted to aftermarket options. By purchasing OEM building parts, firms can avoid constant substitutes and fixings, ultimately saving money and time in the lengthy run.

Improved Precaution

Implementing OEM construction parts can bring about a considerable improvement in safety actions on building sites. OEM parts are particularly made to fit and work correctly within the machinery they are intended for, guaranteeing ideal performance and lowering the danger of breakdowns that could jeopardize security. By utilizing OEM parts, building business can maintain the stability of their tools, decreasing the chances of accidents or failures as a result of incompatible or damaged components.

In addition, OEM components undertake strenuous testing and quality assurance procedures to fulfill sector criteria and specs. This dedication to high quality and reliability converts straight into review improved security at work site. Workers can have confidence in the tools they are utilizing, knowing that it is geared up with real OEM components that have actually been verified to perform securely and successfully.

In enhancement to lowering the likelihood of equipment-related crashes, OEM components also add to a much safer workplace by advertising correct functioning of equipment and adherence to safety procedures. Overall, spending in OEM construction components is a positive action in the direction of boosting precaution and guaranteeing the well-being of workers in the construction sector.

Extended Tools Life-span

Making use of OEM building and construction parts can dramatically prolong the operational life expectancy of tools on construction websites. Initial Devices Supplier (OEM) parts are engineered to specific requirements, guaranteeing compatibility and ideal efficiency within the equipment they are developed for. By utilizing OEM building components, building and construction companies can keep the integrity and performance of their machinery, bring about extensive devices life expectancy.

One key benefit of OEM building and construction components is their high quality and reliability. These parts are produced to satisfy the exact same requirements as the original parts, guaranteeing an appropriate fit and performance. This precision in design and construction decreases the threat of early wear and tear on the tools, eventually enhancing its long life.

Moreover, OEM components usually come with warranties, supplying included assurance to construction business relating to the longevity and efficiency of the parts. This warranty insurance coverage can offer satisfaction and monetary protection in instance of any type of unforeseen concerns, better sustaining the expanded life-span of the tools. By buying OEM construction parts, construction business can guarantee that their equipment operates effectively for an extensive period, maximizing efficiency and lessening downtime.

Streamlined Maintenance Procedures

Having actually established the advantages of OEM building components in prolonging the functional life expectancy of equipment, a concentrate on structured maintenance procedures ends up being vital for making certain ongoing efficiency and reliability on building sites. Streamlined maintenance processes Full Report describe the systematic strategy taken to upkeep equipment and equipment with precision and timeliness. By sticking to a well-structured upkeep schedule that includes normal inspections, cleaning, lubrication, and minor repair services making use of OEM components, building and construction business can reduce downtime and protect against pricey failures.

Executing an aggressive maintenance method not only improves the general performance of the devices however also adds to a much safer working setting for construction workers. By promptly dealing with any kind of issues that arise and changing damaged components with OEM components, the danger of mishaps because of tools failure is considerably reduced. Additionally, structured upkeep procedures can result in set you back savings in the long run by staying clear of major repairs or visit substitutes that might have been avoided via regular maintenance. Ultimately, prioritizing structured maintenance procedures with OEM building and construction parts is necessary for taking full advantage of performance and ensuring seamless procedures at work site.

Verdict

In the world of construction procedures, the reliance on Original Equipment Producer (OEM) building parts plays an essential duty in preserving the effectiveness and performance of hefty machinery and tools on job sites.Carrying out OEM building parts can lead to a considerable enhancement in safety procedures on building sites.Utilizing OEM building components can dramatically lengthen the operational life expectancy of equipment on building sites. By utilizing OEM building and construction components, building companies can preserve the honesty and functionality of their equipment, leading to extended tools life expectancy.

Having actually developed the advantages of OEM building components in prolonging the functional life-span of equipment, an emphasis on structured maintenance procedures comes to be extremely important for making certain ongoing efficiency and integrity on building sites.

Report this page